Sustainability is key for consumers today, especially within the kids’ fashion and lifestyle industry where we create for the next generations. As a broad word that refers to so many different areas, from production and sourcing to certifications and design, sustainability acts as a catch-all term.

For our fourth installment of our Fil Rouge series covering subtopics of our seasonal theme, « Made With Love, » let’s dive deeper into the details of how some outstanding actors in our community incorporate sustainability into their processes. Though all the brands selected to exhibit at Playtime Paris and Playtime New York produce ethically, these 18 stand out to our team for their initiatives. Whether new brands or industry staples, they are incorporating sustainability into their businesses in a variety of ways. Join us as we learn more about what these labels are doing to produce as sustainably as possible!

For Töastie Co-Founders Kirstie and Lucinda, sustainability is largely about longevity and nurturing a sincere connection with nature. “We’re inspired by the idea of equipping children to fall in love with nature, because we protect what we love,” Kirstie told us. “If our products help spark a sense of adventure and connection to the outdoors, while being made responsibly and thoughtfully, then we feel we’ve contributed positively to both childhood and the planet,” she explained. Kirstie and Lucinda look at designing children’s outerwear differently. Rather than scaling down adult designs, Töastie creates outerwear that performs technically and gives kids complete freedom of movement – all while using ethically sourced materials and responsible production methods.

“Becoming a B Corp was a huge milestone for us,” Kirstie said. “It formalized what we’ve always believed, that businesses have both a duty and an ability to be forces for good,” she continued. Obtaining this certification required a rigorous, holistic assessment of their environmental practices, ethical manufacturing, governance, community impact, and transparency. “It pushed us to measure our impact more thoroughly and gave us a framework to keep improving,” Kirstie explained.

From the materials they use to their partners and the way each garment is constructed, sustainability is embedded into every decision Töasite makes. Prioritizing recycled or eco-conscious materials, ethically certified factories, and timeless designs that are made to be loved and worn for as long as possible are just a few of the ways sustainability leads their decisions. “Our aim is to create outerwear that is gentle on the planet but tough enough for wild childhood adventures,” Kirstie said.

“Outerwear is one of the most technically demanding clothing categories,” Kirstie told us. “Balancing performance, durability, and responsibility is challenging,” she continued. They overcome these challenges by partnering with exceptional suppliers who share their expectations and keep pushing material innovation forward. Töastie was an early adopter of using recycled post-consumer plastic bottles. rPET was a natural choice for their rainwear, as it offers exceptional performance while giving new life to materials that would otherwise go to waste. They worked closely with their fabric mills to engineer a premium outershell that met their environmental standards without compromising function or comfort. For their padded collections they use eco-friendly Sorona®. Made from recycled plastics and corn, this blend mimics the qualities of genuine down. It provides a fill that is soft, light, thermo-regulating, and extremely breathable while being gentle on the planet.

These innovative materials are paired with relentless testing and refinement to give their products longevity. Töastie has a Preloved | Reloved platform incorporated into their site, allowing families to return their much-loved pieces to be resold or given a new life. “This initiative is particularly special to us,” Kirstie said. “A child’s favorite coat can be passed on to another child or become part of a magical quilt that is sold to support families in need through our charity partner,” she explained.

All of Töastie’s designs are made with durability at their core so that they can accompany many childhood adventures, be outgrown, passed down, and loved a long time. “Every detail, from sensory-friendly linings to lightweight insulation, is crafted to support a child’s comfort outdoors. In parallel, we work with certifications, audited factories, and traceable supply chains to maintain integrity at every stage,” Kirstie said. Sustainability is a mindset for her and Lucinda, and they’re constantly working to further improve.

Club Trésor has completely reimagined the creative process of a fashion brand. Rather than starting with themes, colors, and moodboards, their process begins with the fabrics themselves. « We search for dormant stock textiles, sometimes forgotten for decades. The moment we find them, they become the foundation of the collection, » Sarah, one of the brand’s Co-Founders, said. She and Avril both have backgrounds in luxury women’s fashion, and they joined forces in 2023 to envision this new design model for a childrenswear brand.

Starting with what already exists, Club Trésor works almost exclusively with dormant stock fabrics. From the 1950’s to today, they source these fabrics in ateliers and factories near their production facilities. “In France, we work with a small, human-scale atelier. We visit often, developing prototypes side by side,” Sarah told us. Thanks to the size of this atelier, they’re exceptionally flexible. “They can bring new designs to life very quickly, allowing us to create true limited series,” Sarah explained. For their jersey pieces, Club Trésor partners with a Portuguese factory that also produces for renowned luxury houses. “Their craftsmanship, impeccable quality, solar-powered facilities, and outstanding working conditions perfectly align with our values,” Sarah said.

This small-batch production is a deliberate choice Sarah and Avril made. It ensures they never overproduce, protects the integrity and value of each design, and allows them to respond creatively to the unique fabrics they find. While this model works well creatively and aligns with their values, it does have limitations for wholesale. Sarah and Avril navigate this challenge by complementing their upcycled limited editions with a small selection of styles made from fabrics that are carefully selected and locally sourced. As recycled and certified as possible, this hybrid approach allows them to broaden their offer.

As mothers themselves, Sarah and Avril are familiar with the issue of rapid obsolesce for children’s fashion. This frustration was a key driver for them to create Club Trésor. “We wanted to rethink children’s clothing by creating evolving silhouettes that can last up to two years, then be passed on while retaining their emotional and functional value,” Sarah said. Their evolving trousers grow through adjustable cuts and carefully considered silhouettes.

The thoughtful designs for longevity and use of dormant stock makes Club Trésor truly unique. Upcycling also allows them to dramatically reduce their environmental footprint. “We give a second life to existing textiles, reviving forgotten stockpiles and transforming them into pieces designed to last for years,” Sarah told us. The brand’s mascot, Bobby the Beaver, perfectly embodies their sourcing strategy. “He carries a shovel, a symbol of how he digs for hidden treasures,” explained Sarah. “These treasures are the forgotten, abandoned fabrics we uncover in warehouses and ateliers and lovingly bring back to life,” she continued.

Club Trésor is now expanding into knitwear, a category that has been particularly challenging to find dormant stock materials. “For now, we work with sustainable, recycled, or certified yarns while continuing our search for vintage knitstock that meets our standards,” Sarah said. She and Avril want to extend their circular sourcing model to every category they produce. Through Bobby and this incredibly instinctive, tactile approach to design, Club Trésor is showing that sustainability can be fun and emotionally engaging for parents and kids alike.

Blending clinical credibility with joyful design, Ocean Olive is proof that responsible skincare for kids can be effective, thoughtful, and fun. Having lived with eczema herself and seeing her son go through it too, Founder Jemila turned more than a decade of experience in allergy and asthma care into Ocean Olive. Born at the intersection of medicine and motherhood, the brand has been shaped by both clinical experience and real life at home. “Our hero product is the Whipped Gel Nourishing Eczema Spot Treatment,” Jemila told us. “It’s a lightweight, steroid-free gel-cream that’s designed to calm, support, and protect eczema-prone skin in babies, children, and parents,” she explained.

This thoughtful pink formula took over three years and 20 iterations to develop. It is focused on barrier-supportive, microbiome-friendly ingredients carefully selected for sensitive skin. “Children’s skin is more delicate and reactive, which significantly raises the bar for safety,” Jemila said. One of the biggest challenges as she was developing it was cost. “We invested in clinical trials to support our safety claim for babies as young as 3 months old. This added time and expense, but is essential when caring for vulnerable skin,” Jemila told us. Balancing this level of rigor with responsible sourcing and accessibility is a constant, intentional effort.

Working with suppliers that are transparent around sourcing and manufacturing has been a priority for Jemila. “We partner with suppliers who align with ethical labor standards and fair-trade principles whenever possible,” she said. Through long-term relationships and ingredients that are gentle, effective, and appropriate for compromised skin, Ocean Olive is creating products families can truly rely on.

Jemila, Founder of Ocean Olive, and her son

Jemila, Founder of Ocean Olive, and her sonThe brand produces in small, intentional batches to avoid overproduction or unnecessary waste. Their primary tubes are made with post-consumer recycled materials, while their secondary packaging is FSC certified. “Every decision, from formulation to packaging, is made with longevity, responsibility, and real family use in mind,” Jemila told us. The goal she set out at the start was to create skincare families could trust without hesitation, that would be effective for babies, kids, and adults. Jemila has remained dedicated to this goal, while staying honest about where Ocean Olive is and how it is committed to improving.

“Our process is guided by clinical reasoning. We formulate with intention, test rigorously, produce in small batches, and package responsibly,” Jemila said. This is all wrapped up in Ocean Olive’s modern brand world that brings their “Think Pink” energy to serious skin care. As the brand grows, they continue to explore more packaging innovations and ways to further reduce their environmental footprint while maintaining their high safety and performance standards. “Sustainability isn’t about perfection. It’s about progress,” Jemila said.

Durability, functionality, and playfulness have been at Molo’s core from the beginning. Driven by a shared passion, the close collaboration of their design and product development teams and their suppliers keeps their focus on testing, performance, and safety grounded. “Our team is so dedicated to creating exciting, high-quality products with personality – pieces we can all be proud of,” Rikke, the brand’s Product & Marketing Director, told us.

At Molo, responsibility is an ongoing process that starts with design. By creating well-crafted products, they ensure their collection’s longevity. “Materials must work for children. They need to be comfortable, durable, and functional,” Rikke explained. Molo works from a clear material strategy, prioritizing certified fibers. These include GOTS and OCS-certified organic cotton, GRS-certified recycled polyester, and viscose derived from FSC-certified wood sources produced in closed-loop systems. Their padded outerwear uses Thinsulate™ insulation, while Molo’s swimwear achieves sun protection through tightly woven fabrics rather than chemicals.

Certifications are key at Molo. “To me, responsibility is about being transparent, both with ourselves and the people who choose our products,” Rikke said. “We see third-party certification as a concrete tool for transparency and accountability,” she continued. Molo is certified to GOTS, GRS, and OCS standards, all of which are certified by Ecocert Greenlife (license number 197496). The certification process is demanding, with detailed documentation, regular audits, and ongoing monitoring across the supply chain. “For me, the demanding aspect is exactly why certifications matter,” Rikke said. “They help ensure that responsibility is built into the way we work, not just how we talk about it,” she explained. Certifications give Molo a solid framework for doing things properly and continuously getting better as they work with long-term suppliers to keep improving quality and reducing unnecessary waste.

Molo

MoloAs a brand with a global reach, Molo believes in growing thoughtfully rather than quickly. Rikke told us they prioritize long-term partnerships, stable production planning, and consistent standards across markets, even if that means slower growth. Safety is their top priority, with all products being developed according to European and international safety standards. “Every season we conduct independent testing for chemical safety, fire resistance, and UV protection,” Rikke said.

Molo is always striving to do better. They continue to work on reducing resource use, improving data transparency, and exploring more circular solutions. “Responsibility is not static. Our approach evolves as new knowledge and better solutions emerge,” Rikke told us. Molo doesn’t claim to be an entirely responsible brand, and is careful not to overstate their impact. What matters to them is continuous improvement, honest communication, and respect for the people and processes behind their products. “Most importantly, it’s about remembering who we design for. Children experience the world with curiosity and openness, and we have a responsibility to create products that respect both them and the world they are growing up in,” Rikke said.

Celebrating five years this month, Mon Coeur is a brand born from the desire to make something that cares equally for children and the planet. Following the birth of her own son, the founder, Louise, decided to launch this adventure to create quality, comfortable, colorful clothing responsibly. The brand is based in New York, with all of their production taking place in Portugal. « We work with family-run production houses. Their craftsmanship is passed down through generations, meaning we get to work with experts in the field, » Louise told us. These partners are key because it’s not easy to find suppliers that will produce responsible collection sizes, find solutions for achieving vivid colors, and that meet Mon Coeur’s quality standards. These decisions require work and expense for the brand, but it’s completely worthwhile.

Sourcing as much as possible near their production houses, Louise always ask what recycled options are available when discussing fabric composition. “We incorporate recycled and upcycled materials as much as possible, and look for printing processes free of harsh chemicals and that use less water,” Louise said. She told us that the thread for their embroideries is made of recycled materials, so sustainability is literally woven into Mon Coeur’s products. The quality is equally as important as the composition. Durable, soft materials mean they will be able to last from one kid to another, and be comfortable enough to be loved by every child that wears them.

From swim trunks and accessories made with Seaqual Yarn spun from recycled plastic bottles and fishing lines to blends of cotton and recycled cotton and even recycled tulle, Mon Coeur is constantly innovating and finding more responsible ways to produce clothing kids will love.

One of the key aspects of Mon Coeur’s sustainability strategy is working with others. One of these partners is the Billion Oyster Project, an organization in New York City building oyster reefs to restore marine life. « Their team does an amazing job connecting with young students and educating them about the environment, which is something we aim to do as well, » Louise told us. « This capsule collection is a conversation starter. It’s a way for kids and families to connect with the ocean, and a reminder that even the smallest hands can make waves, » she continued.

The brand has also teamed up with the retailer Many Moons, a circular online store offering consumers the opportunity to purchase archival inventory at a reduced price. « Many Moons is offering a highly curated selection of brands that also prioritize the planet. They’ve really tapped into an important part of circularity in an elevated way, » Louise told us.

Recently, Mon Coeur has started partnering with another local NYC organization, Little Essentials. “They provide children’s supplies and parenting education to families living in poverty,” Louise explained. “This fall we donated some production samples and archival inventory to their warehouse,” she said.

In addition to these collaborations, Mon Coeur works thoughtfully to make use of fabric strikeoffs from their production process. From hosting events with them for children to sew their own custom tote bags to a Billion Oyster Project launch dinner with gift pouches made from strikeoffs, Mon Coeur comes up with creative solutions to avoid waste.

Education is also key for Mon Coeur. “Sustainability is a big topic, so we work hard to make our sustainability story easily digestible. We want customers to love the quality and design of our products, but also appreciate the thoughtfulness that goes into them,” Louise told us.

Coocoonari was born from a deeply personal starting point. The founder, Konstantina, had twin daughters born with extremely sensitive skin. This led to an exploration of truly organic, chemical free materials, which resulted in the brand’s very first rattle. After three years of research and refinement, Coocoonari emerged with carefully selected suppliers, a thoughtful combination of organic materials, and a design approach inspired by nature. “Each toy is conceived as a design object shaped by natural materials and a quiet, considered approach to making,” Konstantina said.

All of Coocoonari’s products are handmade in their small atelier in Athens. “By producing locally and slowly, we avoid excess and create pieces meant to be cherished,” Konstantina explained. Their small group of makers love craft and art, working with close attention and great care. “Artistic expression is encouraged and given space to evolve, allowing creativity to remain an essential part of the process,” Konstantina told us. They work with GOTS certified organic cotton that is safe for the soil, the makers, and the children who play with their toys. Their other key material is naturally hypoallergenic kapok, a light, plant-based fiber that requires minimal processing and no synthetic intervention. “Together they reflect a quiet, mindful approach to quality,” Konstantina said. “The materials are pure, thoughtful, and lasting, resulting in products created with care for both children and the world they’ll grow into,” she continued.

Design process of Coocoonari

Design process of CoocoonariProducing baby essentials sustainably comes with unique challenges. Materials must meet the highest safety standards while remaining natural, non-toxic, and responsibly sourced. This balance is not always easy to achieve. “Sustainable materials are often more costly and less widely available, especially when choosing small-scale, ethical suppliers,” Konstantina told us. Producing in small quantities also takes time and care, contrary to the speed and volume of conventional manufacturing.

Despite these challenges, choosing a slower, more intentional path is essential for Konstantina when creating objects for the earliest, most sensitive stages of life. For her, sustainability is about making with intention and care. “Sustainability is a commitment to respect the child, the maker, and the environment while leaving as little trace as possible on the world we share,” Konstantina said.

Sustainability is always evolving for Coocoonari. “I’m continuously refining sourcing and production, while actively working to minimize waste by reusing and recycling fabric offcuts,” Konstantina shared. She is also pursuing a long-term vision to make Coocoonari a fully biodegradable brand by choosing every material with its full life cycle in mind.

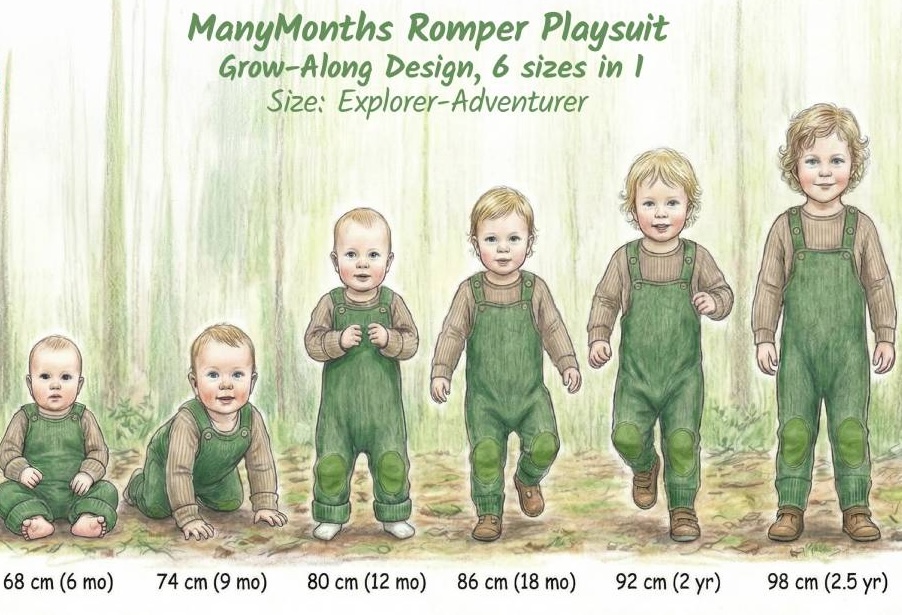

ManyMonths was born in the cold, long winters of Finland from a mother’s frustration. Having begun with importing carefully chosen pieces for her own family and friends, Founder Bettina started to see ways they could be improved. “That led to me designing my own items, including some of the early garments like our Body/Shirts and Elephant Hoods. These later became core pieces of ManyMonths,” she told us. Bettina created ManyMonths to make garments that would grow with children, rather than be outgrown. “The idea was simple, but demanding,” Bettina said. “Design natural-fiber clothing that works with children’s bodies, development, and everyday life, allowing one garment to be used across multiple growth stages, seasons, and more than one child,” she continued.

Instead of constant novelty, ManyMonths creates one Natural Woollies collection and one ECO Hempies collection per year. This allows them to focus on refinement and continuous product development rather than reinvention. Their core material is high quality merino wool, which is known for its natural temperature regulation, breathability, and comfortable hand. No chemical treatments are applied, meaning the wool maintains its natural properties and longevity. Hemp and organic cotton are also incorporated where durability and structure are needed, like on knee patches. « Our materials and accessories are certified and sourced through long-term suppliers, » Bettina said. « We prioritize quality, traceability, and consistency over novelty, » she explained. Color is also key for ManyMonths. « Living in Finland means six to eight months of limited daylight. Color brings warmth, visibility, and joy, and is developmentally important for children, » Bettina told us.

Diagram of how ManyMonths’ garments evolve

Diagram of how ManyMonths’ garments evolveAs for their grow-along concept, ManyMonths’ sizing is based on developmental stages rather than just height or age. Each category reflects a phase in a child’s physical, cognitive, and emotional development. “This affects proportions, mobility needs, and functional details, not just measurements,” Bettina explained. Using this system, nineteen traditional sizes can be replaced by five to eight ManyMonths garments. This is achieved through small construction details that make all the difference. For example, their Body/Shirts have foldable cuffs and adjustable, removable bottom parts that allow them to be used as shirts later on.

« To me, sustainability means creating garments that can be used by one child and passed on to the next one,” Bettina told us. The self-cleaning properties of their natural wool means less shopping, while their evolving designs mean families need fewer items. Their garments also include picture-based labels, helping children recognize which are theirs independently before they can read. Repairs are seen as signs of garments being loved and lived in, which is why every piece comes with extra thread and buttons.

By working with the same manufacturing partner year after year and producing a limited number of collections, ManyMonths builds a shared knowledge with them. They produce based on pre-orders to avoid overproduction. To help ensure their garments last as long as possible, they spend time educating their customers on useful tips for care and repairs. All of these actions bring their community together to make a more sustainable system. Bettina perfectly summarized this in saying “Sustainable design and responsible manufacturing can only exist when they are supported by conscious choices. Slow fashion isn’t something a brand can do alone. It requires designers, manufacturers, retailers, and families to value natural fibers, chemical safety, longevity, care, and repair together”.

Though not always labeled as “sustainability,” Senger Naturwelt has been committed to using natural materials, simple forms, and craftsmanship since its beginning in 1985. Having been formalized and strengthened through certifications and audits over time, these values continue to be upheld today. “What started as an intuitive approach has evolved into a structured, transparent sustainability strategy,” explained Jessica, the Head of Brand Management at Toynamics, Senger Naturwelt’s distributor. “For us, sustainability is not a trend or a single decision, but rather a mindset that shapes every step of our work,” she continued. Jessica explained that longevity is a key factor of sustainability, especially when it comes to children’s toys. “Toys that are loved, repaired, passed on, and used for many years are among the most sustainable products a child could have,” she said.

The longevity and safety of Senger Naturwelt’s products is carefully conceived. Their production is based on certified natural materials and long-standing partnerships. Using primarily GOTS-certified organic cotton and responsibly sourced wool, their timeless designs are produced through a process that combines traditional craftsmanship and modern certification standards. “Many steps are deliberately kept simple and partly manual to allow for careful quality control and attention to detail,” Jessica told us. Working closely with partners who share their commitment to fair working conditions, transparency, and high quality standards is another key factor for Senger Naturwelt. They avoid overproduction and waste by focusing on timeless designs and thoughtful quantities. Children’s toys must comply with high safety standards, especially when using organic materials, so each product goes through extensive testing.

Senger Naturwelt is continuously working to keep improving. Currently, they’re exploring packaging solutions, ways to reduce transport-related emissions, and how to optimize internal processes to use resources more efficiently. “We also see education and communication as important areas for improvement,” Jessica said. This entails helping customers understand materials, care, and repair in order to extend the lives of their products. By communicating thoughtfully with their customers about the value behind their products as well, Senger Naturwelt addresses the challenge of cost posed by ethical production. “Certified materials and responsible production are significantly more expensive,” Jessica explained. “We address this by making conscious design choices, reducing unnecessary complexity, and communicating to our customers,” she said.

Senger Naturwelt itself is GOTS-certified. This was important for the brand because it covers social criteria and environmental responsibility, in addition to the use of organic materials. “It requires full transparency across the entire supply chain, and includes regular audits and strict documentation,” Jessica said. This rigorous and continuous process is essential for the brand to create trust and accountability with the families that love their comforting companions. “Parents place a great deal of trust in the products they choose for their children. We take that responsibility very seriously,” Jessica told us. “Our goal isn’t perfection, but honesty, consistency, and continuous improvement. We always have the child, the people behind the product, and the planet in mind,” she concluded.

For Founder Laurie, Flap Happy is about saving the earth and its children, one swim hat at a time. Born from a personal struggle with skin cancer for both Laurie and her husband, she set out to build a brand that would help keep children safe from the sun’s rays as they enjoy the outdoors. She designed the original Flap Happy UPF 50+ Flap Hat to protect the faces and necks of her own children. From that one design, this UV-protective pioneer has become a staple in the kid’s market for swimwear, hats, and accessories that keep kids safe.

Sustainability has been equally as important from the start for Flap Happy. “Living by the ocean and raising my family in a coastal community made the issue of plastic pollution impossible to ignore,” Laurie told us. She decided to turn this environmental problem into a solution. “Our specialty fabric begins with post-consumer plastic bottles. They are washed, chopped into flakes, melted into chips, and then transformed into fibers,” she explained. These fibers are then woven into high quality swim fabric that is soft, durable, and long lasting. On average, four bottles are repurposed for each Flap Happy product. Additionally, their designs are timeless, making it easy for retailers to carry styles across seasons and reducing waste from overproduction.

Rather than using chemical treatments to achieve their UPF 50+ products, Flap Happy builds the protection directly into the fabric. The tightness of the weave and structure of the fibers themselves naturally block 98% of UV rays. This ensures the protection doesn’t wash out or wear off, making it safer for children and better for the environment.

“Swimwear is one of the most technically demanding categories to produce sustainably,” Laurie told us. The fabrics must meet strict requirements for durability, stretch, colorfastness, chlorine resistance, comfort, and child safety, in addition to consistent UPF protection. This makes sustainable materials that meet all these standards more complex and costly to source. “We’ve been able to overcome these challenges through long-standing, collaborative relationships with our suppliers and factory partners,” Laurie told us. “They understand our expectations and share our commitment to quality,” she continued. Together, Flap Happy and its partners continue to produce high quality swimwear and hats that meet their standards and stay true to their sustainability goals.

Flap Happy collections were manufactured in Los Angeles for 28 years, but have since moved production overseas in order to keep the brand accessible for families. A transition that was not taken lightly, Laurie went to China personally to visit factories and meet the people behind the production. “We are proud to still be working with those same factories nearly 10 years later,” she told us. They’ve been able to build long-term, transparent relationships based on trust, quality, and mutual respect with these suppliers that are aligned with the brand’s values.

For Laurie, sustainability means acting with care for children, workers, and the planet. “It’s about creating products that are made responsibly, last longer, and truly serve a purpose,” she explained. It also means constantly evaluating ways to improve. She sees each season as an opportunity to take another step forward. “After experiencing skin cancer personally and within my own family, sustainability isn’t an abstract concept – it’s deeply human. Protecting kids today while preserving the world they’ll grow up in tomorrow is what drives everything we do,” Laurie said.

Rooted in a blend of Nordic and Swiss values honoring simplicity, quality, and responsibility, minimalisma was founded to create timeless, seasonless styles in pure, natural materials. “We are a small brand with close supplier relationships, which allows us to be hands-on,” the brand’s Founder and Creative Director, Maja, told us. “We work with a small, trusted group of suppliers, many of whom are family-run businesses we’ve collaborated with for years,” she continued.

At minimalisma, they believe in producing where the expertise lies. This has led them to trusted partners across Europe and Asia depending on the material and skills required. Their GOTS-certified organic cotton collection has been knit and sewn in Hungary by the same supplier since the beginning. For their silk products, there is no better place to produce than China. Rooted in tradition and expertise, minimalisma’s seamless silk and wool collections are made there. “It’s where the knowledge runs deepest and the full production process can happen in one place,” Maja said. “This ensures better quality, reduces handling, and minimizes unnecessary transport, making it more sustainable too,” she explained.

Having traveled to China extensively in previous roles and now to regularly visit minimalisma’s partners and review production in person, Maja has observed there are many outdated assumptions about producing in China. « What I see is hard-working, skilled people, often running family-owned businesses with care and pride, » she told us. Minimalisma’s finished products are transported from China to Europe on trains following the ancient Silk Road, significantly reducing their carbon footprint.

Though they worked with GOTS-certified factories found through the organization’s supplier directory since the beginning, it took time for minimalisma to obtain their certification, though not for a lack of responsible actions. “As a small, one-woman business with two kids, I didn’t have time for the heavy administrative work required to apply for GOTS certification,” Maja told us. This made the brand’s certification all the sweeter when it was achieved in 2021. “It’s a certification I’m very proud of. Not because it changed how we work, but because it confirms what has always been true for our organic essentials production. It’s also a clear, trusted sign for our customers,” Maja said.

Sustainability is woven into everything minimalisma does. The brand’s core styles are knitted on tubular machines, resulting in zero-waste patterns. Equally technical and thoughtful, this creates garments that are incredibly comfortable and free of side seams. They encourage mindful care and repair to their garments, but because their styles are all made from biodegradable, natural fibers, they gently return to the earth at the end of their life. Their color palettes are independent of the seasons as well, making it simple to mix-and-match across collections and extending the life of every design.

Today, minimalisma is focused on trying to clarify their size guides to reduce returns and their environmental impact. Sustainability has been and remains at the core of everything they do. “We are not perfect, but we are consistent. We are committed to making thoughtful, long-lasting choices, both for our kids and the planet,” Maja told us.

16 years ago, the founder of TANE organics, Sheree, saw a blank space in the market for a well-curated, heirloom quality childrenswear collection centered around luxurious organic cotton. From this spark has grown a responsible brand free of chemicals and built in partnership with fair trade Peruvian artisans. After decades in the ready-to-wear space, Sheree used her design skills and expertise to mentor and partner with these artisans. “I believe providing work can elevate one’s self esteem and confidence,” Sheree told us. TANE provides consistent work and pay for these artisans, and ensures their safety and health through regular inspections. They even offering cottage industry set-ups that allow their artisans to work in homes.

TANE uses GOTS-certified organic cotton to craft their collections. « This means that at an environmental level, the organic cotton fibers are grown without the use of pesticides or synthetic fertilizers, » Sheree explained. « Organic farming also means it protects the farm workers, water quality, and soil erosion, » she continued. By Using GOTS-certified low-impact dyes, Azo dioxide free fabrics and yarns, and finishing their garments with a non-toxic process, TANE organics are truly clean. They also incorporate baby alpaca, a fiber indigenous to the Peruvian Andes, for their winter collections.

TANE’s thoughtful business model is designed to circulate quality clothing that continues to tell stories and lighten the impact on our planet. « Producing in small batches means there is more attention to detail and perfection. It allows us to produce well-crafted products that can be passed on, shared, and treasured intentionally, » Sheree told us. « I feel strongly that sustainability is a commitment which demands consistency, » she continued.

TANE organics

TANE organicsTANE believes in integrating environmental, ethical, and social responsibility into their luxury products. By focusing on quality, longevity, and craftsmanship, while also minimizing their negative impacts, TANE creates sustainable luxury. Valuing transparency, fairness, and the integrity of great design, they deliver a high end product that is intended to be passed on for generations. “We believe that our support of positive environmental and community outcomes makes TANE products more than just a purchase,” Sheree said.

For Sheree, TANE has always been about mutual growth and the elevation of artisans’ crafts and visibility. “Our strength in textile, fabric, and stitch development made for an easy transition to explore collaboration by designing products to market,” she explained. The brand’s dedication to impeccable craftsmanship and quality materials allows TANE products to be seen throughout resale sites. They are also exploring ways to partner with circular marketplaces to connect their community to recyle-to-repurpose options. “Our quality and service continue to meet expectations,” Sheree told us. This is achieved through diligent work to earn the trust of their partners, the skill of their fair trade artisans, and the longtime and new buyers who have shared TANE’s journey. “The longevity of our brand means the world to me,” Sheree said.

Since it launched 15 years ago, sustainability has been woven into how Gray Label designs, sources, plans, and communicates. « We have approached sustainability as a long-term commitment. Every material, process, or packaging decision is made with the full lifecycle impact, the credibility of verifiable standards, and how a solution works in real life in mind, » Emily, Gray Label’s Founder and Creative Director, told us. Using the softest organic fabrics, the brand’s high quality essentials are minimalist and timeless, creating garments that last for generations in terms of both durability and style.

“Sustainability is embedded in our production through our commitment to using GOTS-certified organic cotton across our collections,” Emily explained. She told us that GOTS is key for the brand because it provides a holistic framework that extends beyond the raw material. GOTS ensures that every stage of production, from fiber processing and dyeing to sewing and finishing, meets strict environmental and social standards. “We work with a small, carefully selected network of long-term manufacturing partners in Portugal and Turkey,” Emily said. These partners are all GOTS-certified, offering transparency, traceability, and accountability throughout the supply chain.

Gray Label itself is GOTS-certified, meaning every party involved in their production is individually certified and audited. “For us, GOTS was essential because it provides clear, verifiable proof behind our sustainability choices,” Emily said. “It allows us to communicate with integrity and gives our customers confidence that our products are genuinely organic and responsibly produced from start to finish,” she continued.

In addition to their certified process, Gray Label carefully forecasts to minimize overproduction. Using small-batch replenishments and never-out-of stock styles also helps reduce the risk of waste, allowing them to reuse leftover fabrics in future runs.

Gray Label works with a limited number of fabric qualities, two for kids and two for babies. This way, they can continue to refine the fit, fabric, dyeing, and finishing of these soft handfeel fabrics that form the core of every garment. “Choices that extend a product’s lifespan or allow garments to be reused or passed on are considered more impactful than material innovations,” Emily told us. Gray Label opened a circular concept store entirely dedicated to the reuse, repair, and responsible circulation of their garments. Customers were invited to return their Gray Label garments for a voucher towards a new purchase. Items in good condition were resold, while those that were not fit for resale were upcycled or sent to a responsible textile recycling facility. Though this location has recently closed, Gray Label has integrated this concept into their brand store in Amsterdam to keep their circular initiatives active.

“Our production process is defined by simplicity, consistency, and long-term partnerships,” Emily said. With these strong foundations, Gray Label continues to further improve their processes. Currently they are looking into improving efficiency in transportation and logistics, as well as strengthening their circular initiatives. They’re following along closely as the EU makes changes to regulations and recommendations. “We see the Digital Product Passport as an opportunity to further improve transparency and traceability,” Emily shared. “We believe that all clothing should be made with care and integrity. At Gray Label, we work every day to offer products that consumers can feel good about,” she continued. Gray Label is delivering just that, with pieces that last, are considerate of the planet, and respect the people who make them.

There is a deeply responsible process behind the playful backpacks and accessories from Affenzahn. Every product is designed with children’s well-being, fair working conditions, and environmental impact in mind. As part of the FOND OF brand family, Affenzahn brings together high design standards, durability, and a strong commitment to sustainability.

Affenzahn is produced under FOND OF’s comprehensive sustainability strategy which is built on four pillars. The first is human rights. FOND OF has been a Fair Wear Leader, one of the highest ratings given by the Fair Wear Foundation, for seven consecutive years. This means FOND OF works with their factories to analyze risks, implement improvement measures, monitor progress, and define clear remediation systems. FOND OF has been assessed by the Fair Wear Foundation, ensuring this title is merited in terms of safe, fair, respectful working conditions.

The second pillar is about supply chain transparency. 97% of their production volume comes from partners the company has worked with for at least 5 years. These long-term partnerships help to continuously improve quality and enable meaningful sustainability progress.

CO2 reduction is the third pillar of FOND OF’s strategy. They closely monitor their product lifecycles through Carbonfact, which enables them to follow real-time assessments. The use of recycled PET also reduces their CO2 emissions.

The fourth and final pillar of FOND OF’s comprehensive strategy is centered around circularity. They have gradually begun replacing conventional Re-PET with textile-to-textile recycled fabrics. These truly circular solutions will help the brand scale up, rather than producing one-off capsule projects.

Affenzahn

AffenzahnAffenzahn views sustainability as both a responsibility and an ongoing process. It’s a long-term commitment that shapes every decision they make, from how their products are designed to how they are produced, worn, and, eventually, reused. Though there are challenges in supply chain transparency, implementing livable wages, and reducing environmental impact while keeping products durable enough for kids, Affenzahn is doing everything they can to combat them. They have independent audits, work with long-term factory partners, develop clear corrective-action plans, source their materials responsibly, and measure their CO2 and wage structures to constantly keep improving.

At Affenzahn, they firmly believe that joy and responsibility can coexist. Their playful animal designs and interactive details are combined with an advanced sustainability and human-rights system. They continue to write their sustainability story each day, further evolving year after year.

For Oso & Me, creating something that lasts is the most sustainable thing a brand can do for the environment. Their functional, high quality pieces are made with “grow-ability” so they can grow along with children. This is achieved through thoughtful features like adjustable waistbands and clever cuffs. Oso & Me is also going against the fast fashion calendar, choosing to produce in limited quantities instead. “We only make what we believe we can sell to avoid the landfill,” Claire, the brand’s Founder, said. “For us, sustainability means intentionality. It’s the opposite of disposable. It means creating a circular life for a garment, designing it so well that it survives the playground, the wash, and the next sibling,” she continued.

This production model is aligned with the brand’s philosophy of ‘Buy less, wear longer’. « Our production is unique because we don’t design for a single season. We design for longevity, » Claire told us. By pairing their core products that sell all year with limited edition drops, they eliminate any items from going out of style, a common problem in the fashion industry. « We keep a consistent core of beautiful, timeless colors, ensuring that a limited edition drop from this year will perfectly match a piece purchased three years ago, » Claire explained.

By choosing vendors located close to their fabric sources in Peru and India, Oso & Me further reduces their carbon footprint . “This significantly decreases our shipping emissions,” Claire said. They also use glassine bags over plastic, and ship with 100% recyclable paper packaging. “We’re a small company making big decisions, from the chemical-free integrity of our fabrics to the reduction of plastic in our supply chain,” Claire told us.

As they work on ways to further reduce fabric waste, Oso & Me turns scraps into accessories like zip bags and shoppers. They are also exploring a circular economy model that can facilitate the repair and resale of their pieces. “Every time we add an extra inch of grow-ability to a pair of pants or choose a glassine bag over a plastic one, we’re making a pledge to our children’s future,” Claire explained. “We aren’t just making clothes. We’re trying to change the way families consume, one hand-me-down-worthy piece at a time,” she said.

Inspired by a simple, timeless, sustainable lifestyle, Little Gusto is a Turkish brand committed to incorporating sustainability into everything they do. « All of our products are made in our own manufacturing facility through a local, sustainable approach, » Sibel, the brand’s Founder, told us. « Our factory operates entirely on solar energy. Our vehicles are electric. We use certified, environmentally friendly fabrics that are traceable from raw material through every production step, We repurpose leftover fabrics by making toys, small products, or by using them as filling, » she continued. These are just a few of the ways Little Gusto is producing mindfully. « For us, sustainability means acting responsibly with the future in mind. It’s about taking responsibility for our environment, our employees, and our society as a whole, » Sibel explained.

Sustainable production was non-negotiable for her when starting the brand, despite the challenges posed by high-cost raw materials, limited certified suppliers, and finding the balance between quality and price. Little Gusto addresses these obstacles by building long-term partnerships, efficiently planning, and maintaining transparent processes. “Leaving a cleaner world for future generations is a responsibility we take seriously,” Sibel said. “Our brand vision requires building a system that operates in harmony with natural resources,” she continued. The brand uses certified materials like GOTS-certified organic cotton, OEKO-TEX Standard 100 fabrics, and recycled materials to uphold the traceability and quality of their collections. They only work with BSCI-certified suppliers, guaranteeing fair wages, safe working conditions, and ethical production.

The brand itself also carries several certifications. “We hold GOTS, OEKO-TEX Standard 100, and various ISO quality certifications,” Sibel said. “These are important because they verify our claims through independent organizations, which builds trust with families. They also ensure we are regularly audited, keeping us on track with our long-term environmental goals,” she continued.

With a framework aligned with the United Nations’ Sustainable Development Goals, Little Gusto continues to push further. “By linking our own priorities to these 17 global goals, we adopt an approach that strengthens social impact, places environmental responsibility at the core, and creates long-term value,” Sibel told us. This ensures that every step Little Gusto takes contributes to the broader sustainability objectives of the future. They’re working to expand their zero-waste goals, further increase the traceability of their supply chain, contribute more to carbon offset projects, and advance a reuse product model.

Combining a mother’s perspective and a business mindset, Sibel guides the brand with a responsible corporate culture. “We deeply feel the responsibility of being a sustainable brand. For us, this means that everything we do must align with our ethical values,” she explained. They’ve built a community where people who care about protecting children’s spirits and the planet come together. “Through the projects we carry out across economic, social, and environmental fields, we achieve more meaningful and impactful work each day,” Sibel said. For her, sustainability is about taking ownership of her and the brand’s role in leaving behind a clean, livable planet for the babies taking their first steps toward the future.

Hanna Andersson

Hanna AnderssonCreating well-made, durable clothing and pajamas that families can hand down again and again has been at the heart of Hanna Andersson for over 40 years. “Hanna is the most resold premium children’s brand today, reflecting the enduring quality stitched into every piece,” Kara, the brand’s Chief Product Officer, told us. Hanna Andersson is incredibly dedicated to making their products last. They increase their longevity by using responsibly sourced materials like organic cotton, reinforced seams, and fabrics that they’ve rigorously tested for shrinkage, softness, and color retention. “By creating clothes that are designed to be worn, loved, and handed down again and again, we further reduce waste and contribute to the circular economy,” Kara explained. Families know and trust the brand’s “Hanna-Me-Down” quality.

Hanna Andersson has a hands-on approach when it comes to product development. They map their supply chain to follow where materials are coming from and where each product is being made. This helps them to control quality at every stage of the process. “Our team is involved in the details from fabric development to trims and construction. This guarantees that each piece meets our durability standards,” Kara said.

Certifications are also key to the brand, both for itself and its partners. “We rely on trusted third-party certifications to help ensure our materials meet high environmental and safety standards,” Kara said. By consistently adhering to the standards set by third-parties, Hanna Andersson is able to maintain the durability it’s known for. “Third-party certifications provide accountability. They also give a clear, shared standard to work towards with our partners across a complex global supply chain,” Kara told us. At Hanna Andersson, they believe in backing up their sustainability with proof, which is why the brand itself carries GOTS, GRS, and OEKO-TEX certifications.

As a brand that’s been around for decades, Hanna Andersson has seen the industry change. “We continue to learn and evolve as materials, standards, and expectations advance,” Kara said. Ongoing education remains important as best practices evolve. Hanna Andersson balances cost with impact, always viewing sustainability as a long-term investment. “Sustainability is about making thoughtful choices about how our products are designed and made,” Kara told us. “It starts with prioritizing safe, high quality materials like organic cotton and rigorously tested trims, and designing clothes that are built to last and be handed down. It also means staying committed to learning and improving, knowing that responsible practices will continue to evolve,” she continued.

Throughout these shifts, the brand has stayed consistent in their commitment to making durable clothing and pajamas that champion the adventures and joy of childhood. “That long-standing commitment rooted in comfort and longevity is reflected in the success of our Hanna-Me-Down resale marketplace,” Kara said. This platform is a natural extension of the brand’s commitment to longevity, quality, and thoughtful design that families have trusted for generations.

Tea Collection inspires global connection and curiosity with each collection, bringing the beauty of different cultures to children’s wardrobes through fun, heirloom-quality products. As they travel the world to create their collections, they also seek out different avenues for contributing to communities in a meaningful way. Tea Collection proudly donates 10% of their profits to philanthropic efforts worldwide. “Giving back has always been central to who we are as individuals and as a brand. We travel the world for inspiration, so it’s just as important for us to support the communities and children who inspire our collections,” the brand’s Director of Product, Katye, shared with us.

One of their most valued partnerships is with the Global Fund for Children, which supports community-based organizations that create lasting changes for kids where it matters most. « To date, we’ve donated over $500,000 toward advancing the dignity and potential of children globally, » Katye said. They’ve also worked with Elimu Girls, a Kenyan non-profit empowering young women through education and skills training. In 2024, Tea Collection donated $10,000 to this initiative, as well as fabric to support their fashion design program.

In addition to their philanthropic initiatives, Tea Collection maintains long-term relationships with manufacturers around the world. “Different product categories are made in different countries based on each factory’s expertise and craftsmanship,” Katye told us. All of their sourcing partners are certified by third-party social compliance auditors. Tea Collection also maintains close oversight through regular visits and trusted local agents, and has their factories sign a workplace code of conduct. “This contract ensures their dedication to fair, safe labor practices. Quality and compliance are the foundations of all our production decisions,” Katye explained.

The natural, renewable fibers Tea Collection prioritizes guarantee the durability of their products, allowing them to live several lives. “Our Rewear program allows families to sell or trade pre-loved Tea and earn rewards. This incentivizes reuse and creates an opportunity for garments to have a second or third life,” Katye said. Much of their collection is made with 100% cotton, and they’ve shifted their swimwear to recycled materials as of this year. “All of our materials are carefully sourced to align with our commitment to quality, sustainability, and responsible production,” Katye explained.

At Tea Collection, they believe sustainability is both a practical commitment to quality and production choices as well as a way to inspire conscious, positive impacts in everyday life. “For me, sustainability goes beyond using high quality fabrics. It’s about the broader impact of our actions as a company and how we engage with our customers and communities,” Katye told us. “It isn’t just about what we produce; it’s about inspiring positive changes through community, responsibility, and mindful choices,” she concluded.

While Bobo Choses’ designs are centered around their motto of “Have fun!”, their commitment to sustainability is completely serious. “As a free-spirited, original clothing brand with a touch of humor, we have a creative perspective that acts as a powerful tool for discovering, developing, and imagining new ideas and solutions,” the brand’s Innovation & Sustainability Manager, Cecilia, told us. For her, sustainability is a mindset. It’s about balancing the different dimensions life depends on by enabling environmental and human development, and allowing natural systems to thrive over time. “It requires decisions and activities that meet present needs without compromising future generations,” she explained.

By producing at least 70% of their collection locally in Spain and Portugal, Bobo Choses is well situated to follow strict compliance protocols and carry out continuous research, innovation, and development projects. They work closely with their manufacturers, building relationships that are open and transparent. « There is a local community that is part of the Bobo Choses ecosystem like a family. Many of them have been by our side for a long time now, » Cecilia said. Through partnerships like these, Bobo Choses continues to work to strengthen their traceability and measure their impact so that they can keep evolving in the right direction.

The people behind Bobo Choses’ production process is what makes it unique, as well as the members of their global community. “Our community highly values the origin of our products,” Cecilia said. While Bobo Choses doesn’t have a take-back program in place currently, they actively encourage their customers to plan out product’s second life. “In our care recommendations you can find a comprehensive set of suggestions to give the garments a second life, lovingly and responsibly,” Cecilia told us.

This year, Bobo Choses has reinforced their commitment to innovation by creating a new partnership with Circulose, a sustainable MMCF that is obtained from the recycling of deadstock garments. They are also part of the Canopy program, which is dedicated to protecting ancient forests, and are industry partners at a Horizon Europe project, Polymers 5B, which is developing a new textile material to replace synthetics with more sustainable options. “While there are a lot of challenges in this field, we feel very motivated to contribute to positive change,” Cecilia said. “The challenges are big, but that doesn’t stop us from finding alternative solutions,” she continued.

Bobo Choses’ production process

Bobo Choses’ production process

Thank you to all of these brands for sharing their sustainability stories with us. There are so many different facets to this topic, and the openness with which these brands talk about where they are and where they can still improve is key.

Sustainability isn’t just about dedication. The key component to any brand successfully embarking on a sustainability journey is having the right partners. Relationships, often long-lasting ones, are the reason many of these brands are able to innovate, find new solutions, and overcome the challenges that responsible production methods pose. Stay tuned for our fifth and final Fil Rouge article on collaborations coming soon to Playtime Magazine. In the meantime, check out our first, second, and third Fil Rouge articles to further immerse yourself in our seasonal theme, Made With Love.

Get your pass to meet Gray Label, minimalisma, Coocoonari, Töasite, Club Trésor, and Bobo Choses at Playtime Paris January 24-26. Oso & Me, Tea Collection, Mon Coeur, TANE organics, Ocean Olive, Hanna Andersson, Flap Happy, and Little Gusto will all be at Playtime New York February 8-10. As for ManyMonths, Molo, Affenzahn, and Senger Naturwelt, you’ll find them at both shows this winter.